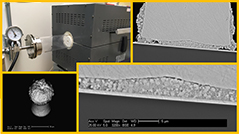

Recognizing the growing need for higher power capability device interconnects, high-end device manufacturers are exploring the possibility of all copper interconnects. Electromigration-resistant copper interconnects can be made using a flip chip dipping process with a copper sintering paste. Subsequent copper sintering to the carrier pad requires a carefully controlled reducing atmosphere. Preparing for member-driven evaluations of such copper sintering systems, the APL has constructed an experimental apparatus for the sintering of copper in a formic acid environment. It will be used for studies of copper sintering kinetics and interfacial bond integrity as a function of time, temperature and pressure.

Archive

- September 2024

- August 2024

- June 2024

- April 2024

- November 2023

- October 2023

- September 2023

- April 2023

- January 2023

- October 2022

- September 2022

- August 2022

- July 2022

- May 2022

- April 2022

- January 2022

- December 2021

- October 2021

- June 2021

- December 2020

- November 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- September 2018

- August 2018

- May 2018

- April 2018

- March 2018

- February 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- May 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- January 2014

- December 2013

- November 2013

- October 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013