- Licensed authorization of design features from IBM and United Shoe Machines’ Dynapert Division allows Universal to manufacture printed circuit board insertion equipment.

- 1st sale of Universal’s insertion equipment to Remington Rand Univac at Utica, NY credited to President Ahearn and Engineer, Phil Ragard.

- Transistors replace vacuum tubes in IBM Computer circuitry. Universal asked to design and manufacture preparation equipment for these and other odd shaped components.

- Universal’s first Sequencer—a machine to select random components from reels and respool insertion sequence is introduced; sold to Western Electric, Chicago.

- Second addition to Bevier Street adds 18,000 sq. ft. for machinery expansion.

- J.D. Ahearn becomes Chairman of the Board; F.H. Lawson becomes Company’s third President & employment hits 339.

[section background_repeat=”repeat” background_position=”center top” background_attachment=”static” background_scroll=”none” border_size=”2″]

Company forms 20-year service club; honors 19 employees in first induction.

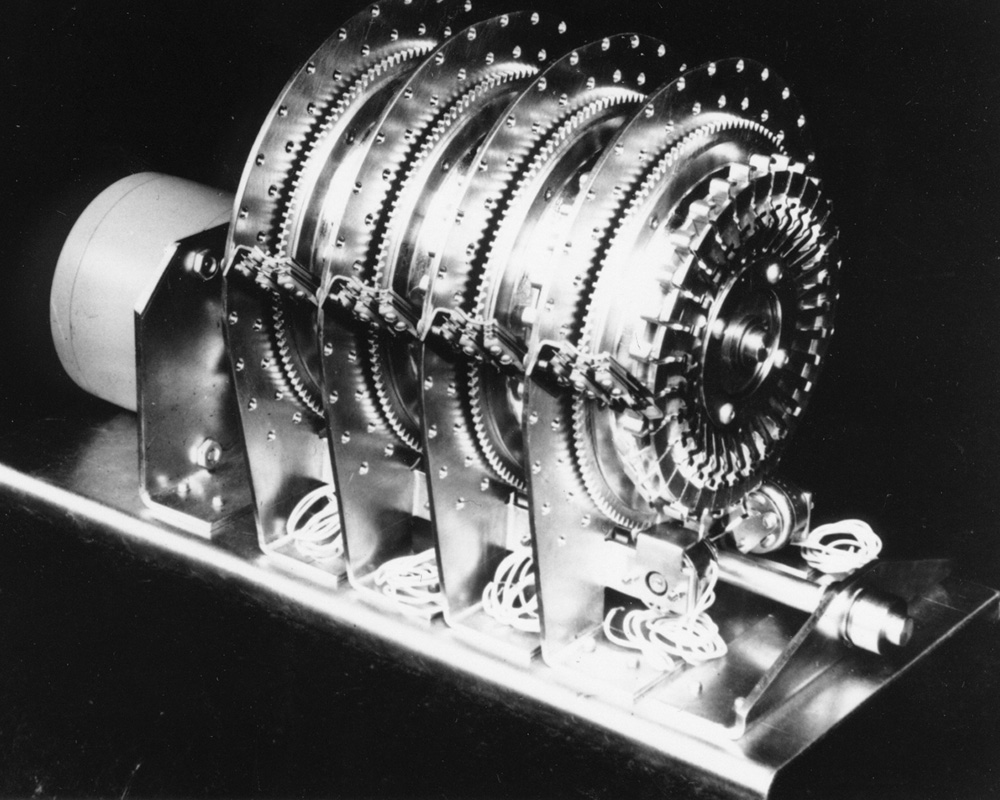

Uniregister® Mechanical Memory, produced in 1962-63. This shift register helped control component process systems.

[divider style=”none”]

[/divider]

Universal forms Mechanized Electronic Assembly business unit (MEA) to provide subcontract component prepping, taping, and insertion services.

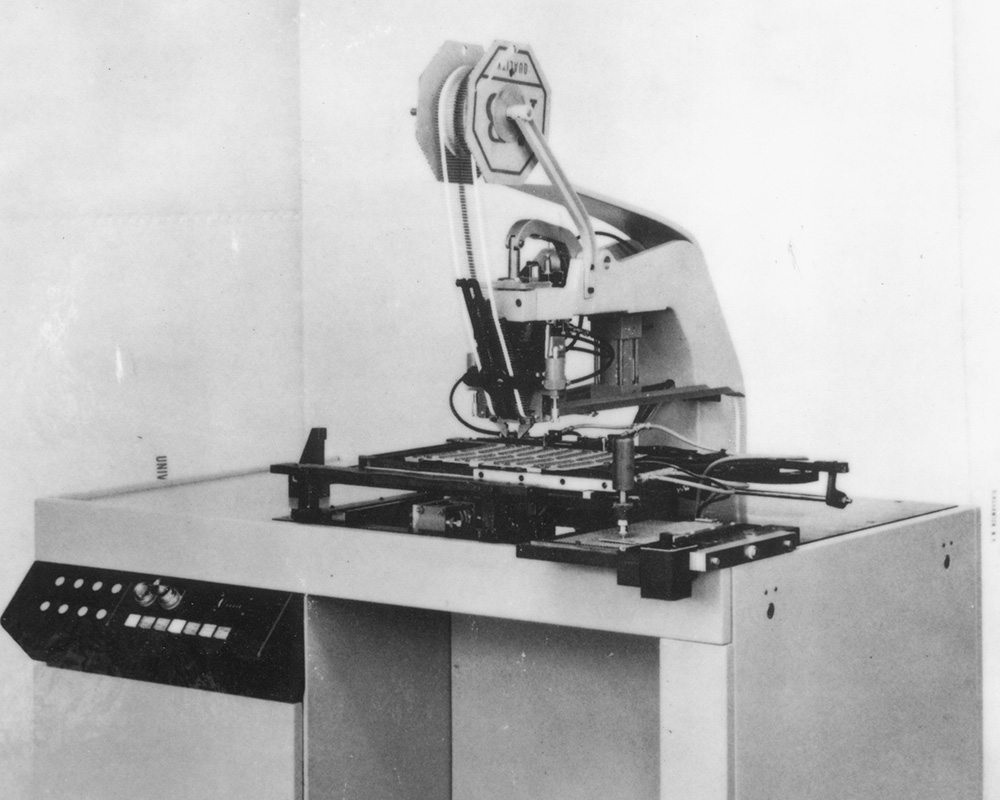

First commercial sale of insertion equipment: Fixed Center Distance (CD) Head Pantograph for axial components designed and built for Remington Rand’s Univac Division-Utica, NY in 1963.

[divider style=”none”]

[/divider]

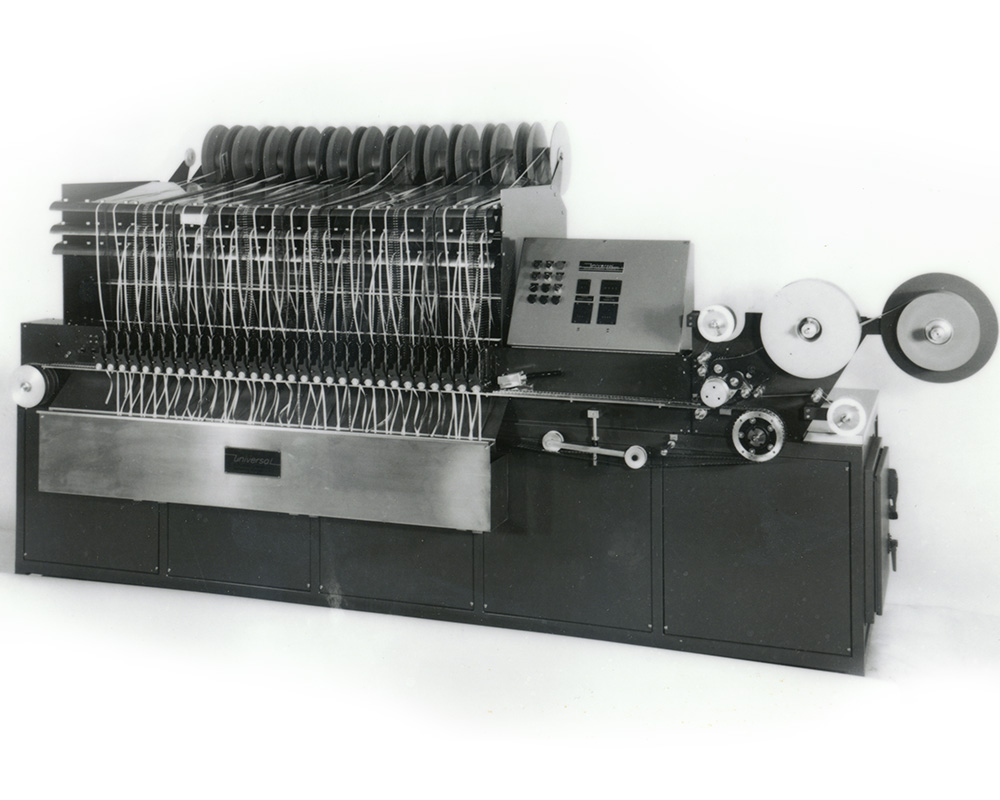

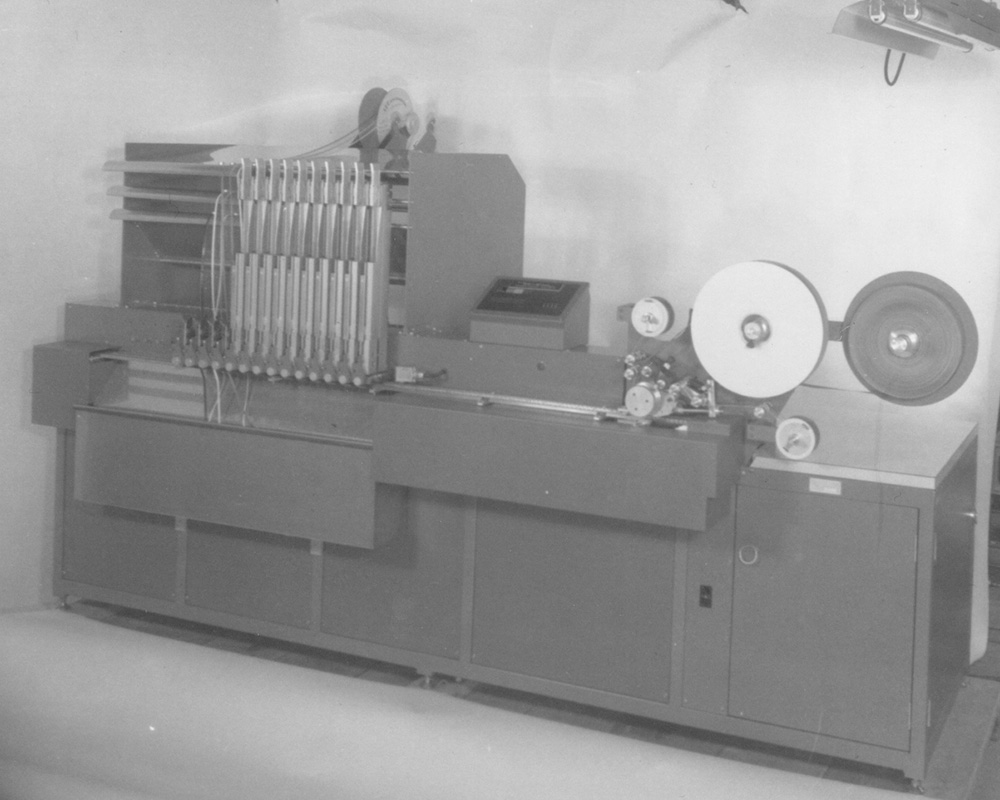

Unisert used reeled components from our “Taping Machine” to populate printed circuit boards. It worked by inserting axial components of a single configuration and value into a PCB.

First Sequencer allowed customers to prepare the assorted component bodies in sequenced order on reels

[divider style=”none”]

[/divider]

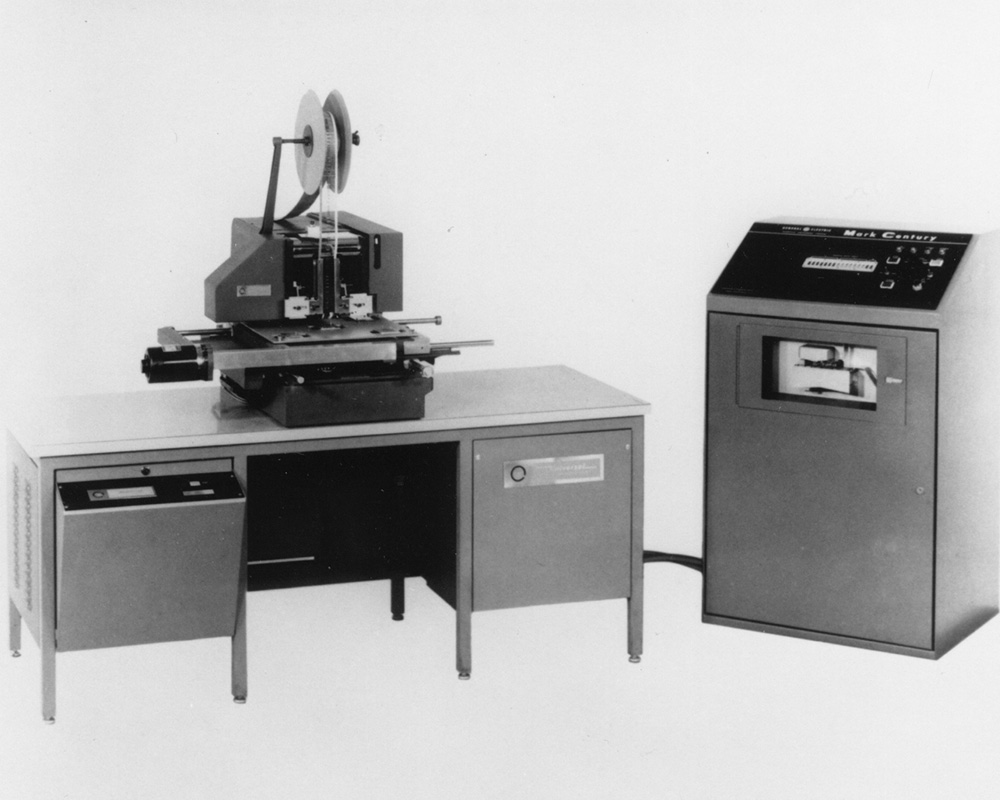

The image above, shows the first VCD Inserter featuring a *solid-state N/C (Numerical Controlled) System enhancement.

When demand for component equipment rapidly grew, Pantograph inserters (shown in foreground) and Taping Machines (shown in background) were produced in the basement at Frederick St.

[divider style=”none”]

[/divider]

Sales engineers and members of the Executive team tour production operations in 1965.

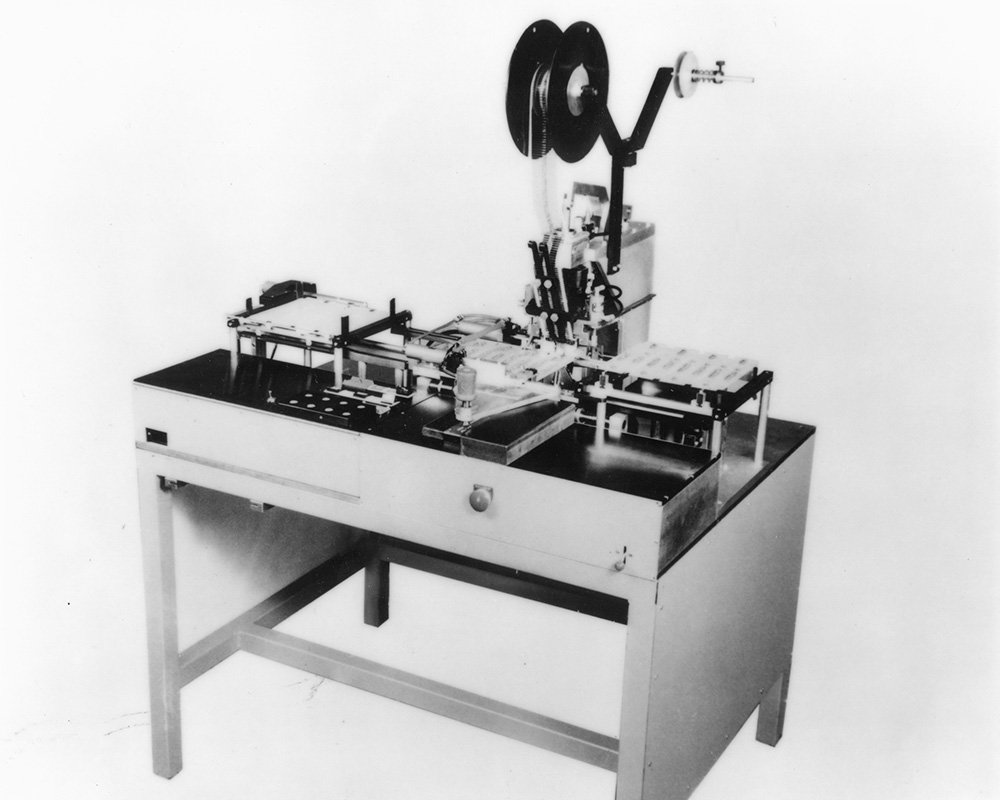

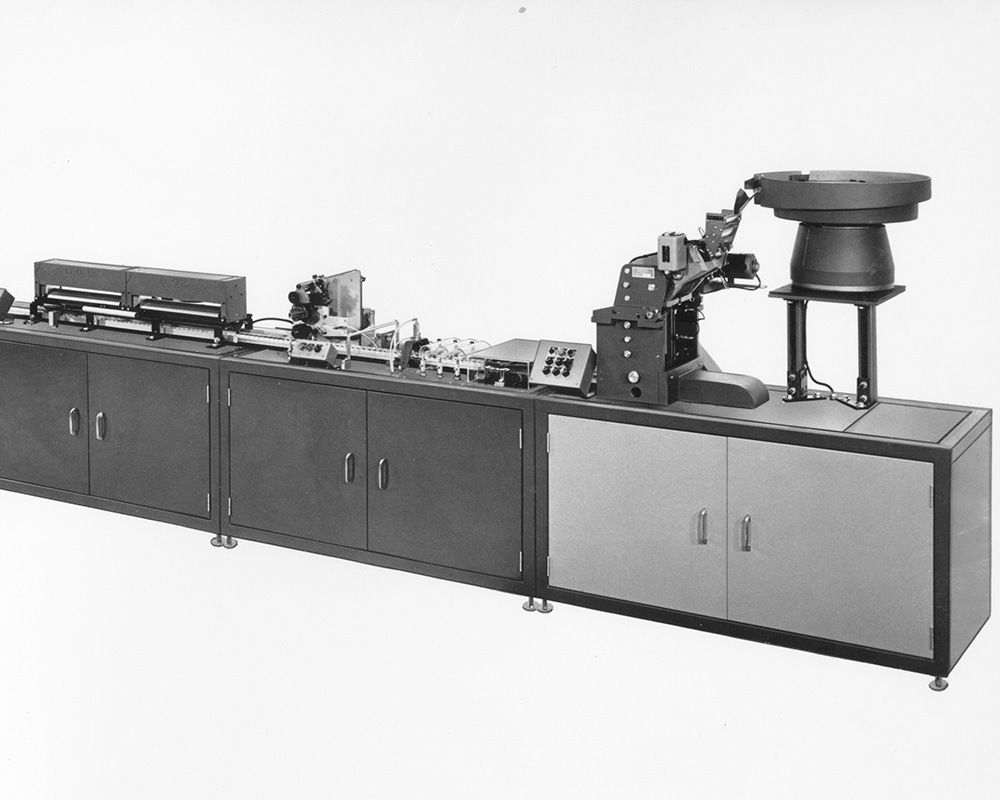

Process line manufactured for TRW in 1966. This Mylar Capacitor Process Line, included: feeding and lead straightening, test and three category sort, outer foil orientation, and printing infrared curing with controlled discharge.

[divider style=”none”]

[/divider]

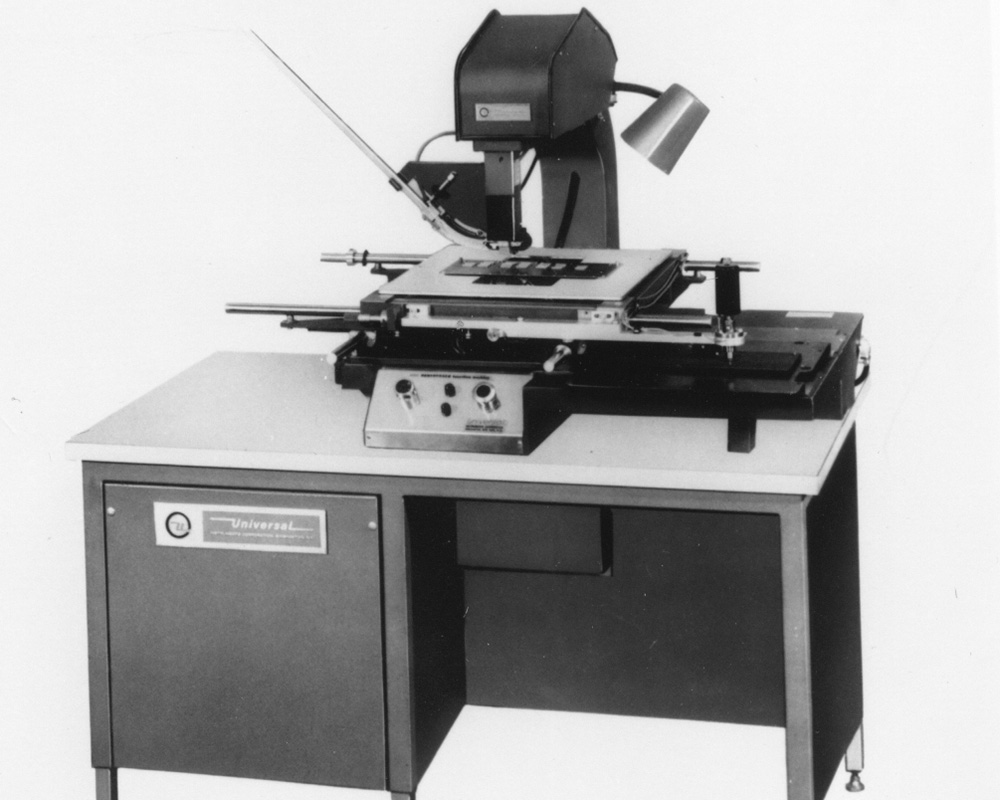

This is the first DIP Inserter that was displayed at a trade show in New York City in 1966.

[/section]

[space value=”50″]

[/space]

A couple additional points in history:

- Universal is once again sought for defense production during Vietnam War by Piccattiny Arsenal (Pennsylvania) and Motorola (Arizona).

- Television had gone from a novelty to the dominant medium of the age and one of the most profound communications tools ever.

- The first hand-held calculator was invented by Texas Instruments in 1967, at a cost of $2,500 each.

- The overall worldwide economic trend was one of prosperity, expansion of the middle class.

- In the second half of the decade, young people began to revolt against the conservative norms of the time, creating a “counterculture” that sparked a social revolution as a reaction against the conservatism, and the war in Vietnam.