December 10,2015 – Understanding the effects of changeover on your manufacturing process and how improving changeover time can help you generate more revenue

If you are looking to boost your output or increase your responsiveness to customer demand, then you need to take a look at reducing your changeovers or setups. If you typically spend one hour to change over a machine or line and you run 8 to 10 setups a week, you’re wasting a whole day a week, or up to 52 days a year, of potential production time! This changeover time can come at a significant cost to your company’s revenue potential! Read on for more as we invite you to “Change the Way You Think About Changeover.”

In manufacturing, changeover is the process of converting a line or machine from running one product to another. Or in other words, the time it takes to go from the last good part of one product run to the first good part of the next product run. Quick changeover is critical to lean manufacturing, because it provides the flexibility to match the product mix to actual demand. In turn, this prevents the accumulation of inventory that can add cost and substantial waste to a value stream.

Changeover can take a few minutes to as much as several hours, and be required several times a day (production dependent). Changeover can be divided into three categories, teardown, set-up and first article build.

- Teardown includes the removal of the previous product, materials and components from the line. It can range from minor to major, requiring complete teardown of the equipment.

- Set-up is the process of actually converting the equipment. This may be achieved by adjusting the equipment to correspond to the next product or by changing non-adjustable “change parts” to accommodate the product. Typically it will be a combination of both.

- First article build is the time spent reviewing the process after it has been restarted. It is characterized by validating that 100% First Pass Yield will be achieved when production resumes.

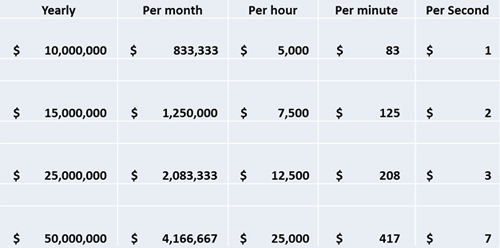

Changeover is one of the largest contributors to SMT line ineffectiveness and lost revenue. The first step in determining the cost of changeover is to establish your yearly revenue generation goals per line and then extrapolate that over time.

Yearly Revenue Generation Goals per SMT line:

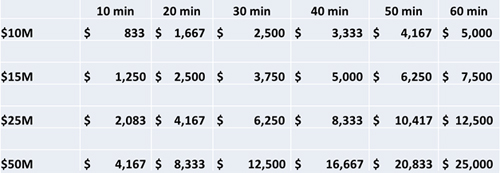

Time in Minutes & Dollars:

These tables assign tangible dollar values to units of production time and highlight two very important considerations:

- Time Lost is not recoverable

- Time Saved enables greater revenue generation

So how do you reduce your changeover costs and increase your revenue generation?

First, let’s start with this question: How should you measure the changeover time of your line; specifically where does it start and end?

- For a single machine, changeover time starts when the machine completes the last PCB of the previous run, and stops when the first PCB of the next job enters the machine.

- For a line, changeover time starts when the last machine in the line completes the last PCB of the previous run, and stops when the first PCB of the next job enters the first machine in the line. Total changeover is more than just downtime of the machines. It should also include the time needed to verify the first assembly, also called first article build.

There are many different methods of calculating your changeover time. However, changeover is just one element of an efficient manufacturing model. A more telling metric is that of Overall Equipment Effectiveness (OEE), which takes into consideration a more comprehensive set of factors: downtime (availability), performance and quality rate.

Want to learn more? Stay tuned for our follow-on blog on ways to calculate OEE.