Automation is defined as the use of largely automatic equipment in a system of manufacturing or other production process. As with any type of manufacturing process, automated assembly is today’s preferred method to reduce costs as well as increase speed.

What are the benefits and challenges of automation vs. manual processes in PCB assembly? Read on to learn more. . .

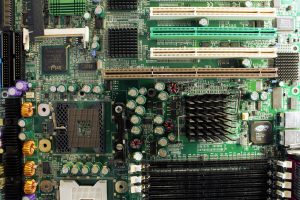

PCBs are at the backbone of today’s electronics. It would be impossible to construct computers, smartphones, tablets, or any modern gadget without them. It is therefore vital to have a dependable, strong, and proven method of PCB assembly.

Originally, all PCB’s were assembled by hand, which at the time consisted only of insertion mount components that were generally larger and easy to handle. As the need for accuracy, speed and efficiency increased automated assembly was developed and began to be adopted. Today, electronic parts have gotten smaller and/or or more complex with every advancement, making it very challenging for human assemblers to manually place them accurately and consistently on the board.

Furthermore, today’s manufacturers utilize every inch of the board tightly packing in components. This makes it very difficult to do consistent manual assembly. There just isn’t the room for operator’s hands or fingers to manually place the parts.

Manual assembly requires multiple skilled technicians to do what one automated assembly line can do at a faster rate. There is also a good chance of human error with manual assembly, whereas an automated system will do its job at the same consistent level of quality again and again.

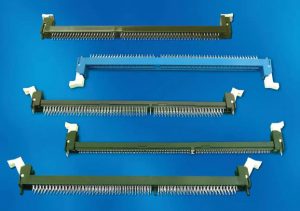

However, manual assembly is still being utilized today for large, heavy and oversized component placement. There are a variety of reasons for this, including:

Perceived Cost of Switching from Manual to Automation

-

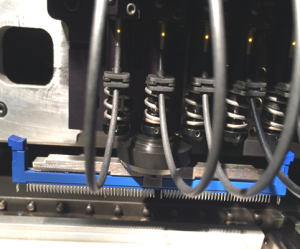

Fuzion delivers. . . Less than 2-year ROI

-

Single machine for all odd-form and standard surface-mount; which equates to lower cost

-

Flexibility for widest odd-form part range

-

14 unique grippers/nozzles, 22kg force; industry-fastest odd-form placer

Component Packaging challenges; components are in non-standard packaging

-

We offer the widest variety of high-speed odd-form feeding options, including tape, tube, tray & bulk!

-

Pick your oddest part and we can help you place them!

Reluctance to change established manufacturing processes; tried and true vs. new

-

Automated component placement delivers superior output, yield & quality vs. manual assembly

-

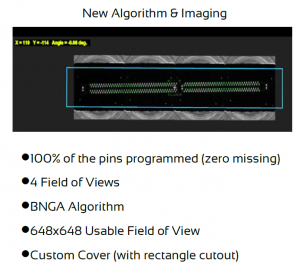

100% pre-insert pin inspection with superior camera vision; eliminates bent or damaged leads for PTH and Press-Fit