June 25, 2015 – Universal Instruments’ Polaris “Hybrid” combines the best of Multi-Process and Servo-Gripper into one machine to provide greater flexibility and better support for your custom manufacturing processes.

Same Cell – Several Applications

Key Technologies

- Dispensing

- Pick and Place

- Driving Screws

- Vision Inspection

- Bar Code Scanning

- Labeling

- Clinching

- Packaging

- Laser Marking

- Height Detection

- Press Applications

- Test/Special Application Handling

- Dispense Weight Monitoring

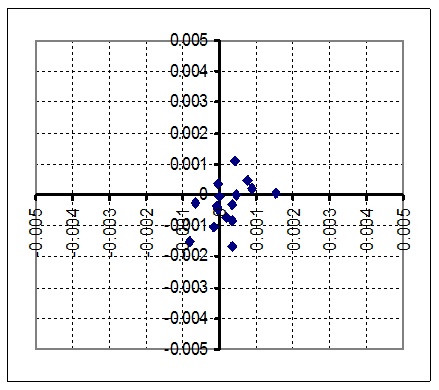

Verified Machine Accuracy

- Every Polaris positioning system is mapped enabling the user to translate CAD files

- The Polaris can be measured using traceable glass boards and components

- Final placement performance for a Servo Gripper or Multi-Process Pick and Place machine is: “X”, “Y” +/- 75 micron @ 4σ; Theta +/- 0.2° @ 4σ; X, Y, & Z repeatability +/- 0.01 mm

Multi-Process Interface

- Standard tool interface allows Polaris to be a platform across multiple work cells (final assembly, odd form, packaging, screw driving, dispensing, etc.)

- Various tools can be used in combinations to achieve custom process requirements

- Modular system and use of standard interfaces results in a cost-effective solution by paying only for needed capability

- Common software interface with all options

Multi-Process Tools/Heads

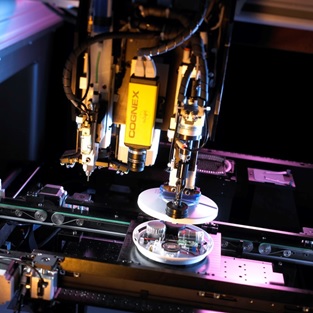

- Vision guidance camera

- Quadrus 2-D bar code scanner

- Cognex insight color inspection camera

- Keyence color inspection camera

- Vacuum and gripper pick and place tools (pneumatic and servo)

- Dispensing valves

- Screw drivers

- Height detector

- Future applications driven by customer requirements

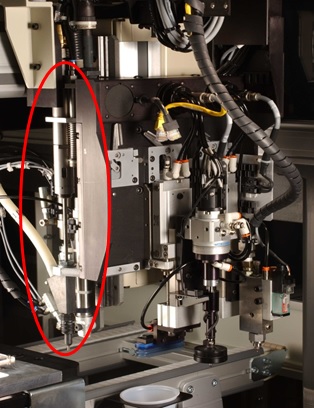

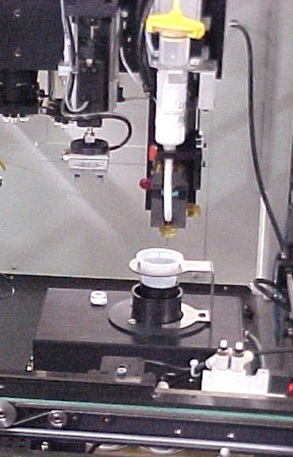

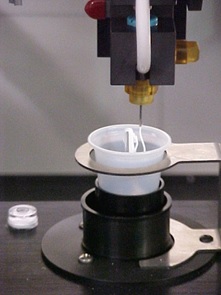

Screw Driving Head

- The head is mounted on the rear of the multi-Process head to conserve a location on the front

- The screw driver that is implemented here is a Deprag, electric drive

- In an effort to conserve space, this driver was re-packaged specifically for Polaris

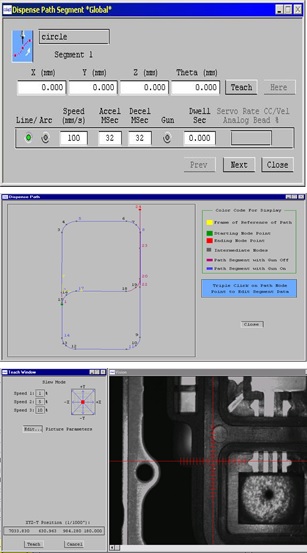

Dispense Path Programming

- Program the machine using the database and the pre-defined shapes

– Speed, acceleration, deceleration, dwell can all be programmed off-line - Look at a dynamic view of the dispense path

– Gross programming errors will be caught before any material is wasted using this view - Check the path on the machine before dispensing any product

– The downward looking camera will drive through the programmed path

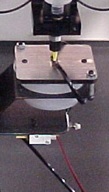

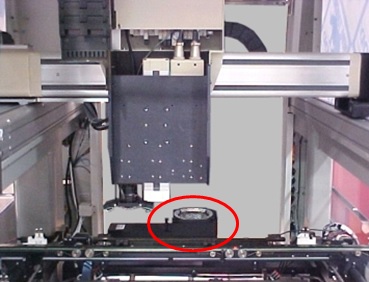

Weight Scale – Dispense option

- The scale can be mounted anywhere on the base frame

- Provides the user with the weight of a programmed amount of material

- The scale is primarily used as an audit process during normal production

- The user controls the number of cycles between audits

Non-Contact Needle calibration

- This dispensing option provides for automatic calibration at the users request or when changing the needle

- This option eliminates lengthy manual steps to define the new x,y,z coordinates

- If the material has a tendency to to adhere to the bottom or outside of the nozzle, an optional cleaning station is available

Inside the Machine – Downward Looking Camera

- Allows fiducials or holes to be used for orientation

- Programmable light levels

- Also enables flexible feeder teaching

Inside the Machine – Upward Looking Camera

- GSM OFA-style camera

- Software supports pattern recognition for through-hole leads and final assembly components

- Programmable light levels

- Enables CAD-driven placements without adjustment

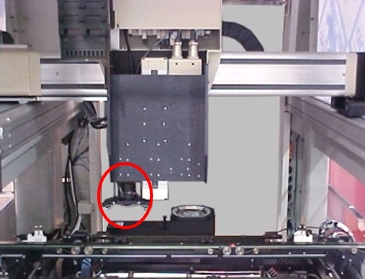

Material Handling – Triple stage product handling

- Provides for a Board in a stage closer to the “Work” area of the machine

- Edge-belt conveyor accepts up to 457 mm x 508 mm (18” x 20”) boards or pallets

- Optional programmable width control (PWC) and tooling pin registration

- None Required! – The machine is modular and can accept non-Universal product handling or simply a work surface for stand alone applications

Contact Stan Earley by +1-607-725-5129 or earleys@uic.com or go to our website https://www.uic.com/solutions/automation/ for more information on Automation.