July 16, 2015 – Various feeding options to meet your assembly needs from Universal Instruments.

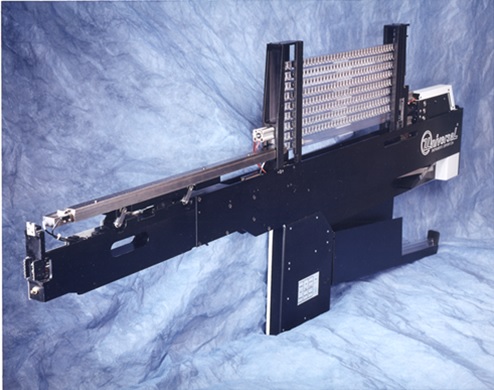

Low Profile Multi-Tube Feeder

- Platform design allows for rapid re-configuration and re-deployment

- Rear tube loading allows for replenishment “on the fly”

- Positive pusher ensures consistent, reliable parts feeding

- Capable of handling tubes up to 25.4mm [1.0”] wide and 23.9mm [.94”] Tall

- Tube length – 482mm [19”] to 610mm [24”]

- Tube reservoir – 216mm [8.5”]

- Consumes two standard feeder slots [40mm]

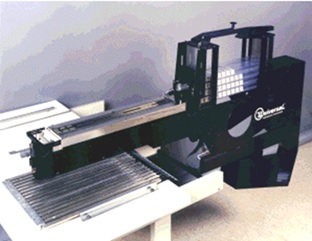

Wide Body Multi-Tube Feeder

- Platform design allows for rapid re-configuration and re-deployment

- Rear tube loading allows for replenishment “on the fly”

- Positive pusher ensures consistent, reliable parts feeding

- Capable of handling tubes up to 115mm [4.5”] wide and 57.1mm [2.25”] Tall

- Tube length – 406mm [16”] to 610mm [24”]

- Tube reservoir – 216mm [8.5”]

- Consumes six standard feeder slots [140mm]

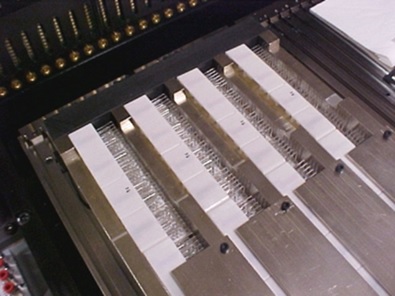

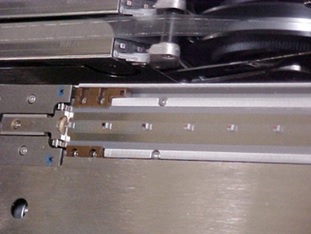

4-Track Multi-Tube Feeder

- Platform design allows for rapid re-configuration and re-deployment

- Rear tube loading allows for replenishment “on the fly”

- Positive pusher ensures consistent, reliable parts feeding

- Capable of handling 4-up tubes 217.1mm [8.55”] wide and 31.42mm [1.24”] Tall

- Tube length – 572.7mm [22.6”]

- Tube reservoir – 282.8mm [11.13”]

[icon icon=”film” size=”small” style=”simple” shape=”inherit”][/icon] Video: 4-Track MBMTF

Expanded Multi-Tube Feeder

- Platform design allows for rapid re-configuration and re-deployment

- Rear tube loading allows for replenishment “on the fly”

- Positive pusher ensures consistent, reliable parts feeding

- Capable of handling tubes up to 45.7mm [1.8”] wide and 57.1mm [2.25”] Tall

- Tube length – 406mm [16”] to 610mm [24”]

- Tube reservoir – 406mm [16”]

- Consumes three standard feeder slots [60mm]

Bowl Feeders

- Bowl feeding is a cost effective means of delivering a device to the machine, higher deployment cost but no packaging costs

- Bowl feeders are designed to separate, sort, and align components for Polaris to pick up

- Some bowl feeders are designed to pre-assemble devices for Polaris to improve the efficiency of a manufacturing line

Edge Stack Feeders

- Used primarily for connectors packaged in tubes, stacked side by side

- Edge stack feeders conserve space on the machine

- The feeder is mounted external to the machine and only consumes 1-3 feeder slots (Width dependant)

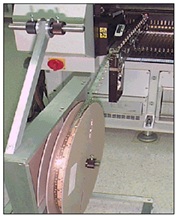

Radial Tape Feeder

- The radial tape feeder is capable of handling both 12.7mm and 15mm bandoleer tapes

- Leads can be cut to length in this feeder, eliminating the need for a cutter inside the placement cell

- The radial lead feeder consumes two standard feeder slots

Axial Tape Feeder

- Accepts standard axial tape format

- Scrap removal interface to Polaris

- Lead bend and forming are available options

Label Feeders

- For placing product identification labels, bar code labels, product set-up labels

- Print on demand and place labels or place pre-printed labels

[icon icon=”film” size=”small” style=”simple” shape=”inherit”][/icon] Video: Dual Printers

Direct Die Feeder

- Places flip chips or circuit up applications directly from wafer

- Accepts wafers up to 200mm (8.0”)

- Die size range from 1mm to 10mm square

- Feeder width: 80mm (3.15”)

- Recurring packaging costs eliminated

Custom Application

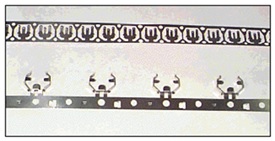

Battery Clip Feeder Features

- Special request to feed and automate battery terminals

- Feeder excised parts from metal tape

- 40 mm width (2 slots)

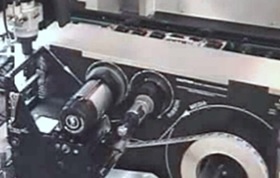

Electric Motor Brush Feeder Features

- Custom feeder to automate electric motor brushes

- Brushes packaged on continuous reel

- Feeder cut parts from tape and presented to machine

[icon icon=”film” size=”small” style=”simple” shape=”inherit”][/icon] Video: Brush Feeder

Forming Leads on TO-220

- Custom Feeder to convert the “in-line” leads of a TO-220 to Staggered lead configuration

- A standard expanded Multi-tube feeder was modified for the task

[icon icon=”film” size=”small” style=”simple” shape=”inherit”][/icon] Video: Cut-Form Feeder

Contact Stan Earley by +1-607-725-5129 or earleys@uic.com or go to our website https://www.uic.com/solutions/automation/ for more information on Automation.