July 2, 2015 – Universal Instruments’ Polaris Junior features multiple standard cell widths with common controls, side covers, and frame structure for a low-cost solution with faster lead times than custom cells. This flexible solution enables cost effective, high-yielding automation of a wide range of mechanical assembly processes for electronics assemblies such as medical monitoring devices, automotive sensors, hybrid, and semiconductor packages.

Scalable size for the application

Scalable Cover Package Design

- Common side covers and frame structure

- Cross members grow to match application needs

- Machine widths from 750mm to 1500mm

- Touch screen user interface front (rear optional)

Control Cabinet Flex Mounting

- The control cabinet can be mounted on the floor or hanging from the back of the machine

Configuration

Gantry Overhangs Conveyors

- Allows for compatibility with wide range of conveyors

- Allows for easy installation and relocation

PLC Control

- Omron PLC control

- Network capable

- PC can be easily added for traceability, file storage, or messaging

Head Interface

- Same interface as Polaris Multi-process

- Any tool created for that interface will be capable of adapting to this cell

Proven Positioning System

- NSK Sealed, lead screw drive

- Servo Driven X and Y axis offered in multiple lengths

- X: 750mm, 1000mm, 1250mm, 1500mm. Y: 800mm

- Pneumatic slides available for simple stroke

- Combinations of Pneumatic and servo are possible

Polaris Junior Application

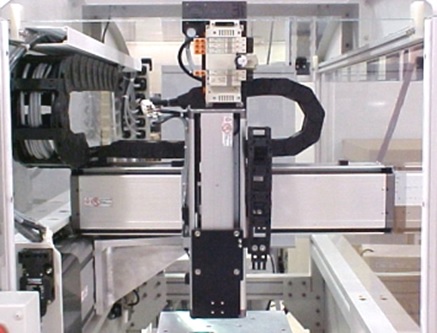

1000mm Junior with Screwdriver

- This machine is a three axis servo machine

- Equipped with a Webber, Electric Screw driver

- The conveyor that the customer selected was MagStar

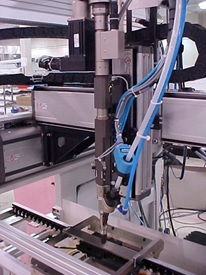

In-Line Press Platform

- This application is built on Universal’s press platform

- This machine is equipped with a servo press from Schmidt technologies

- The press is capable of sensing pressure in 2 oz increments with a maximum of 300lbs

- The structure is capable of pressures up to 2000 lbs

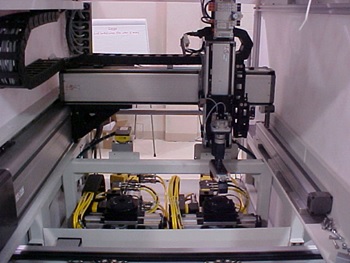

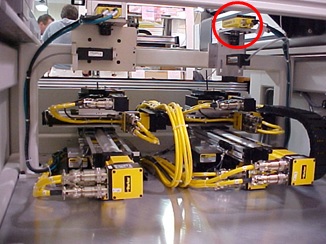

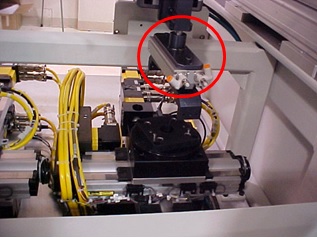

1500mm Polaris Junior

- This application is built on Universal’s Polaris Junior Platform

- The function will be a test handling application

- There will be 5 test nests that the machine will have access to load and unload

- The stages are micro positioning stages for the test nest

- Each stage will precisely position the product using a camera, before applying the probes

1500mm Polaris Junior

- Large Work area for applications

[icon icon=”film” size=”small” style=”simple” shape=”inherit”][/icon] Video: Junior with RF & Shaker

Contact Stan Earley by +1-607-725-5129 or earleys@uic.com or go to our website https://www.uic.com/solutions/automation/ for more information on Automation.