August 17, 2014 – Universal Instruments’ Dr. Babak Arfaei is going to present “Effect of Sn Grain Morphology on Reliability of Lead Free Solder Joints in Thermal Cycling Tests” on August 25 at iNEMI Workshop on Board Assembly & Test Technology in Shenzhen, China.

In an effort to deliver state-of-the-art components that provide more functionality generation after generation, component designers are utilizing significantly miniaturized electric interconnects. The decreased scale of operation for these components is causing a change in the micro-structure and consequently alters the thermal fatigue performance of these solder joints.

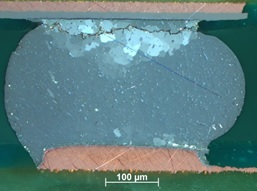

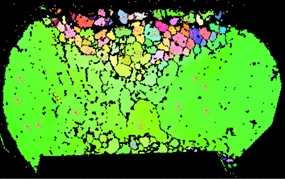

Previous results have elucidated that Sn grain morphology has a significant effect on reliability of lead free solder joints in accelerated testing. This investigation provides further in-depth analysis of the failure mechanism of different solder joints with various solder volume. Important aspects of micro-structure such as precipitate morphology, spacing and Sn grain morphology of LGAs, BGAs, CSPs and QFN are investigated. The effect of micro-structure on initiation of crack, recrystallization behavior and thus failure mechanism of these joints in different thermal cycling profiles is reported. Solder joints were taken out of the thermal cycling chamber at specific intervals of characteristic life and carefully analyzed. This provides an understanding of the micro-structure evolution and the impact it exerts on joint performance.

Ultimately, understanding solder joint behavior provides the end user the ability to select optimized materials and design, which results in improved assembly processes that yield better product reliability and performance.

Here is the preview of some of the presentation’s highlights:

- Many similarities were observed in the failure mechanisms of a variety (BGA, CSP, QFN) of Pb free SAC solder joints which were subjected to one of a variety of thermal cycling regimes. Solder fatigue was observed in all of the samples, with evidence that crack propagation was along grain boundaries of recrystallized regions of the sample.

- Some significant differences in failure rates were correlated with changes in the Sn grain morphologies of these solder joints. Relatively long lifetimes were observed for samples which initially displayed an interlaced Sn grain morphology, as opposed to a beach ball Sn grain morphology.

Click here to learn more about this iNEMI workshop and register. You can also contact the speaker Dr. Babak Arfaei by +1 917-331-5556/Babak.Arfaei@uic.com. For more information about the Advanced Process Laboratory (APL), go to https://www.uic-apl.com/home or contact David Vicari via vicari@uic.com/+1 607-779-5151.

Speaker Bio:

Dr. Babak Arfaei received his Ph.D. in Materials Science and Engineering from Binghamton University, (Binghamton, NY). He is currently a Process Research Engineer at Universal Instruments Co. where he conducts research in the area of reliability of electronic packages. He also serves as a Research Assistant Professor in Physics Department at Binghamton University.

His research interests include mechanical properties of materials, micro-structure and texture analysis of metals, nucleation and growth in metallic systems and thermo mechanical behavior of lead free solders. Dr. Arfaei has published several refereed technical and conference articles on these subjects.