Many of today’s modern electronics utilize press-fit component technology to deliver additional functionality to their products. Press-fit technology offers a compliant connection between a PCB and a plated through-hole and a single pin or connector, which eliminates the need for solder altogether.

What’s so pressing about press-fit and what are the challenges of using this type of component? Read on to learn more. . .

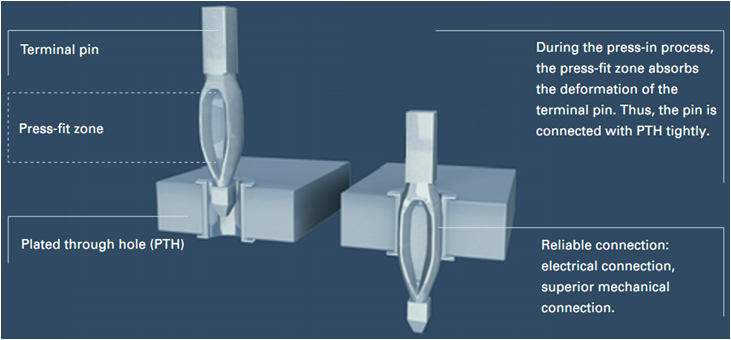

Press-fit technology enables high-quality, solderless electrical connections. With this special connection technique, individual contact parts or entire assemblies are press-fit with press-fit zones in metallized recesses on a circuit board.

As suggested by their name, press-fit contacts are pressed into properly dimensioned plated-through holes on the PCB with gas-tight interference between the contact and the hole.

The terminals (press-fit parts) of a press-fit connector are inserted into through-holes in the printed circuit board, where pressure is applied due to the deformation of the press-fit sections, causing contact between the holes and the terminals to pass electric current.

In other words, the press-fit section of each terminal forms a tight fit with a through-hole in the printed circuit board due to the restoring force generated as a result of the elastic deformation at the time of press-fitting. This tight-fit state maintains the contact to allow electricity to pass through.

Press-fit pin connections are versatile and can be used on both sides of the PCB, which enables flexible, double-sided through-hole and SMT PCB assemblies. Also, as modules shrink in size, press-fit pins can help protect sensitive components and save valuable space in tight pin configurations.

Automotive systems and servers (two markets that utilize a lot of press-fit technology) generate a lot of heat, which can build up in an engine compartment or in a server compartment. Press-fit pins provide a reliable interface that naturally dissipates thermal heat, with a significantly higher heat threshold and lower failure rate than solder joints.

Another advantage of press-fit over wave-soldered connections is thermal compatibility. If secondary soldering is required, it will introduce heat that can damage the PCB and attached electronics. Press-fit technology entirely eliminates the extra heat cycle and allows secondary connections using only force for assembly.

Press-fit connectors are easily repaired, more environmentally friendly, and cost effective. Although press-fit eliminate the risks associated with soldering, this technology has its own challenges, and manufacturers compete with a spectrum of connector products offering press-fit terminations of various design complexities, made from materials with different performance levels.

These key advantages have made press-fit technology a preferred solution for the design of many new products. It has also prompted a growing number of design upgrades of products being migrated from solder-based connections to press-fit technology. Some key driving factors towards the growing adoption of press-fit include:

-

Eliminates risk of dry joints, cracking and other solder formation problems

-

Strong, solder-free, repeatable and highly reliable interfaces

-

Verifiable assembly techniques with integrated force-monitoring

-

Automated Press-Fit assembly processes for consistent results

-

Direct-contact interfaces

-

Excellent electrical and thermal transfer characteristics

-

Resilience when different board materials expand at different rates during thermal cycling

-

High current-carrying capacity for power applications

Press-fit connectors pose their own set of unique challenges during the PCB assembly process, including:

-

How to implement automation and achieve ROI over manual-assembly

-

Wide component variety; different types, heights, widths, etc.

-

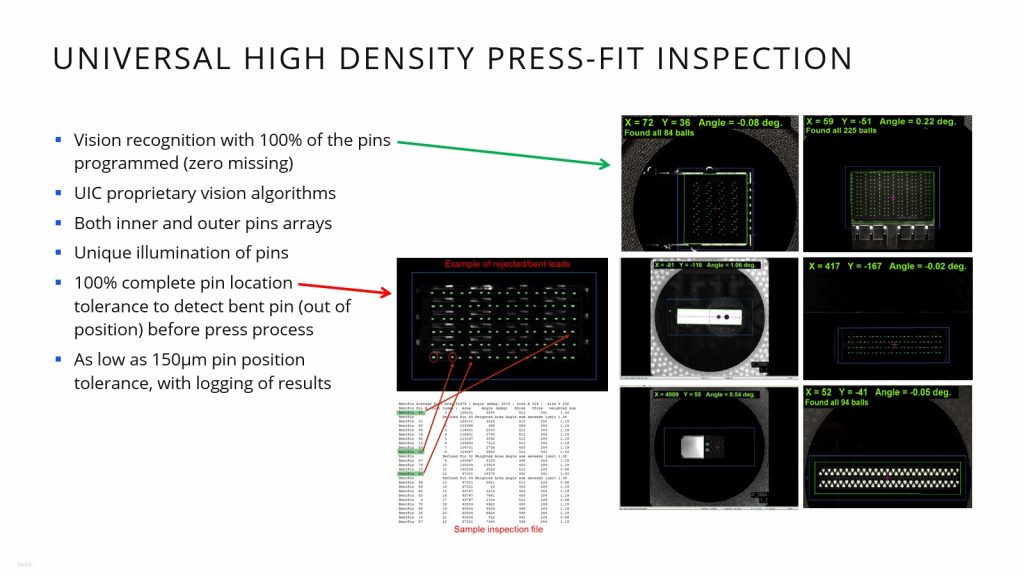

High-density pin inspection requirements

-

Varied component presentation requirements

Universal offers a wide range of solutions that perfectly addresses press-fit challenges.

-

Superior output, yield & quality vs. manual assembly

-

<2-year ROI; 27K cph per module

-

Single machine for all odd-form & press-fit

-

Flexibility for widest odd-form and press-fit part range

-

100% pre-insert pin inspection for bent-pin free production; Unmatched inspection for highest yield

-

Wide variety of high-speed odd-form feeding options (tape, tube, tray)

-

High OEE based on automated feeding: High-speed DTF tray feeder with 40-tray capacity

-

-

14 unique grippers/nozzles, 22kg force; industry-fastest press-fit placer

We are the perfect fit for press-fit! Watch this video below demonstrating 100% pre-insert pin inspection; “2-step” side move for densely “brickwalled” connectors and more. . .